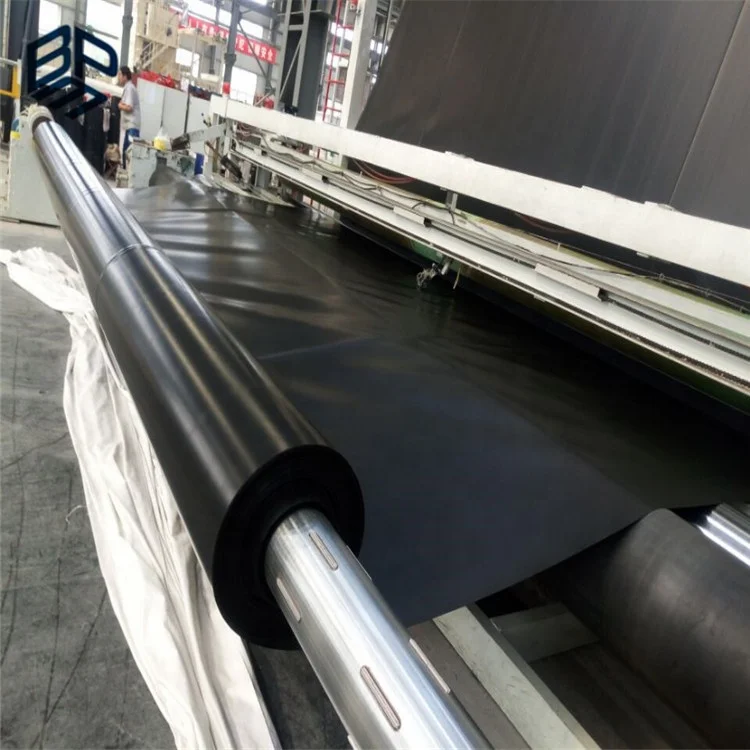

Heavy Pond Liner for Ponds and Waterfalls Heavy Pond Liner

Furniture,Lights & Construction Building Structural Material

FOB Price:US$ 1.00 / Square Meter(s)

MOQ:10000 Square Meter(s)

Payment Method : L/C T/T Others

Keywords:Waterfalls Heavy Pond Liner

Products of the same category