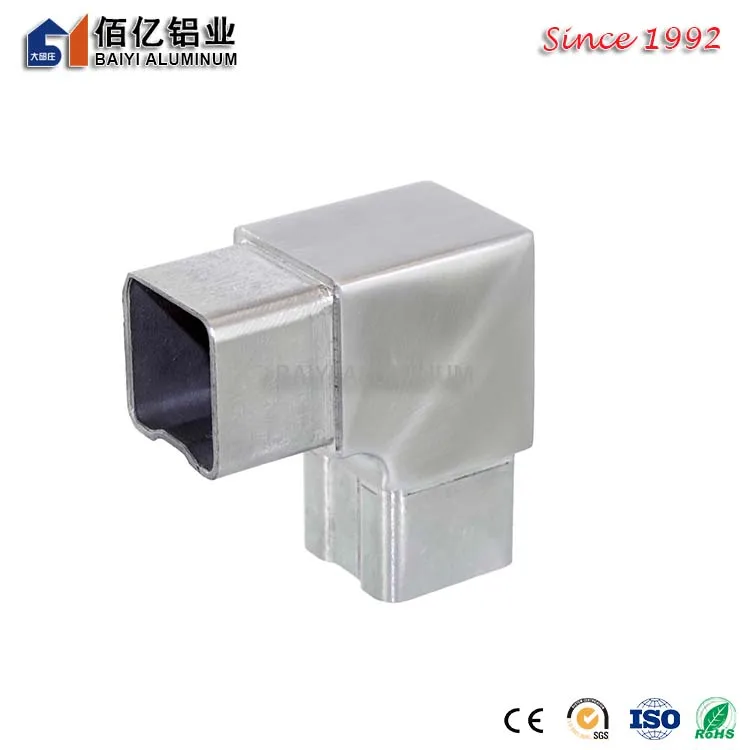

Aluminum Profile

Furniture,Lights & Construction Building Structural Material

FOB Price:US$ 5.00 / Piece(s)

MOQ:10000 Piece(s)

Payment Method : L/C T/T D/P

Keywords:Aluminum Heat Sink Aluminum Industrial Profile

Products of the same category