Hebei Xinnuo Roll Forming Machine Co,Ltd

Business Type:Manufacturer

Main Products: roll forming machinelight keel roll forming machinesandwich panel production lineshutter door forming machinegutter and downpipe forming machinefloor decking roll forming machineHIGHWAY GUARDRAIL ROLL FORMING MACHINESteel Frame & Purlin Machinescorrugated roof panel forming machine

view on mobile

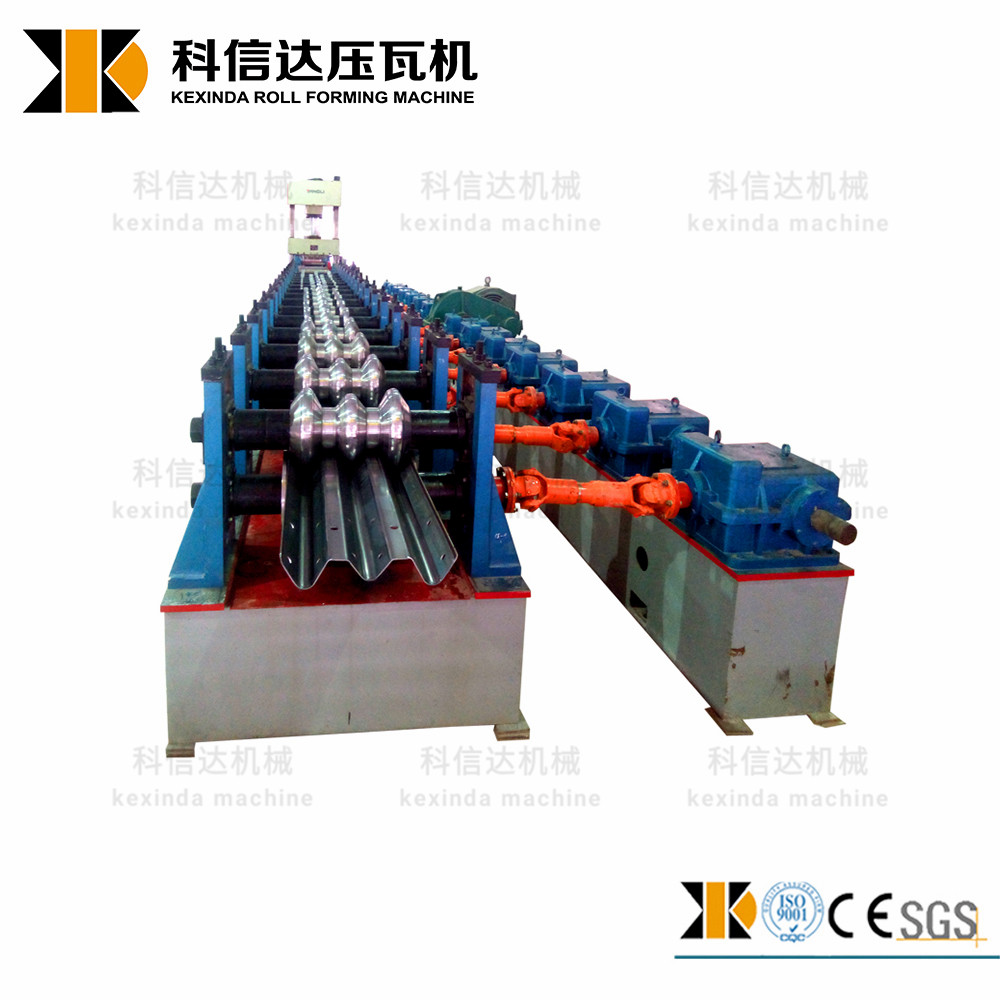

highway guardrail roll forming machine

Manufacturing & Processing Machinery Industrial Processing Machinery

MOQ:1 Piece(s)

Payment Method : L/C T/T D/P Western Union Paypal Money Gram Others

Keywords:roll forming machine Tile Making Machinery roofing sheet making machine tile make machine roofing equipment roofing making machine