view on mobile

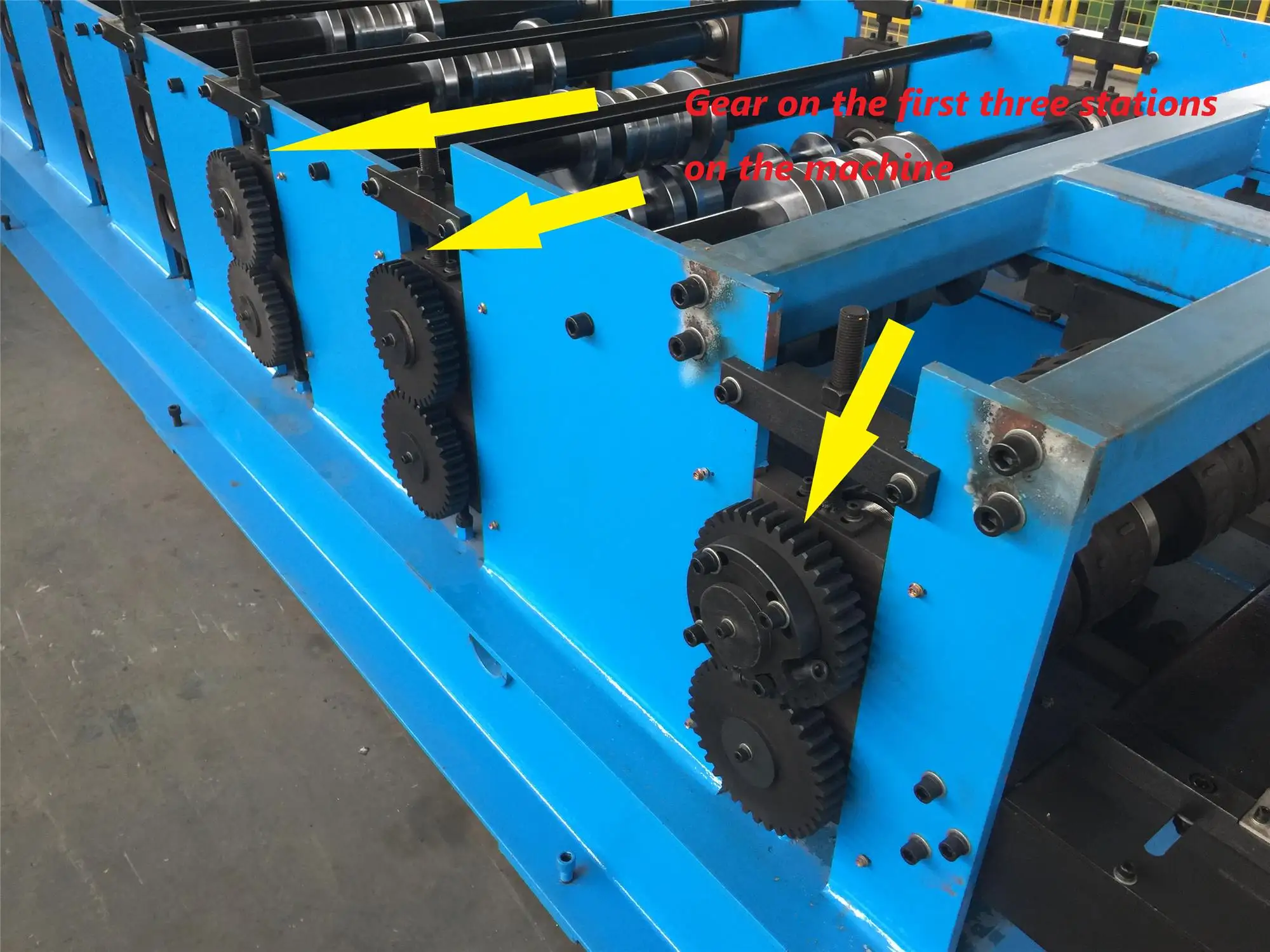

Construction Equipment Floor Deck Roll Forming Machine Tile Making Machinery

Manufacturing & Processing Machinery General Industrial Equipment

FOB Price:US$ 34,000.00 / Set(s)

MOQ:1 Set(s)

Payment Method : L/C T/T D/P

Keywords:Construction Equipment Floor Deck Roll Forming Tile Making Machinery floor deck machine decking machin roll forming machine

Products of the same category