SHIJIAZHUANG YINGYEE IMPORT&EXPORT CO.,LTD

Business Type:Trade service

Main Products: Automatic purlin forming machineLight keel roll forming machineMetal roofing sheets forming machineDecking floor forming machineSteel coils Cut to Length production lineStorage racks forming machineThread Rolling MachinesDoor panels and frames forming machineGuardrail fense forming machineStraighten and cutting machine

view on mobile

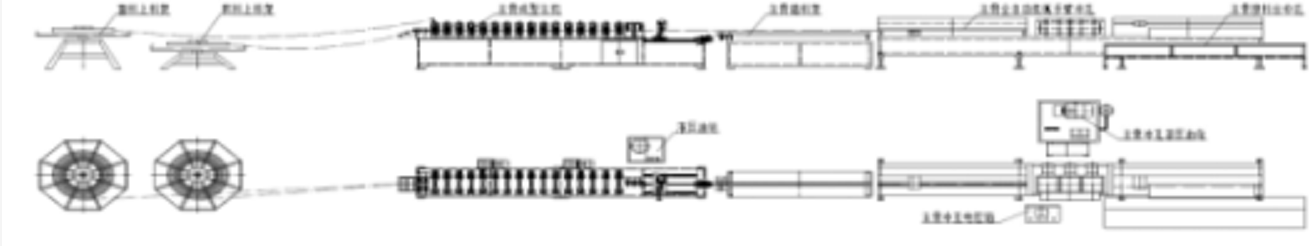

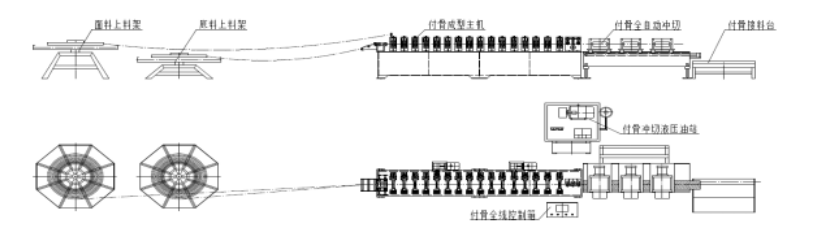

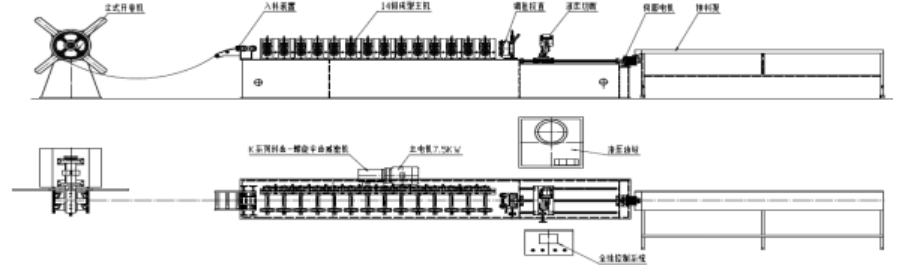

T-ceiling production line

Construction & Decoration Building Structural Material

MOQ:1 Set(s)

Payment Method : L/C T/T

Keywords:T-ceiling machine T-Ceiling production line Main tee cross tee angle