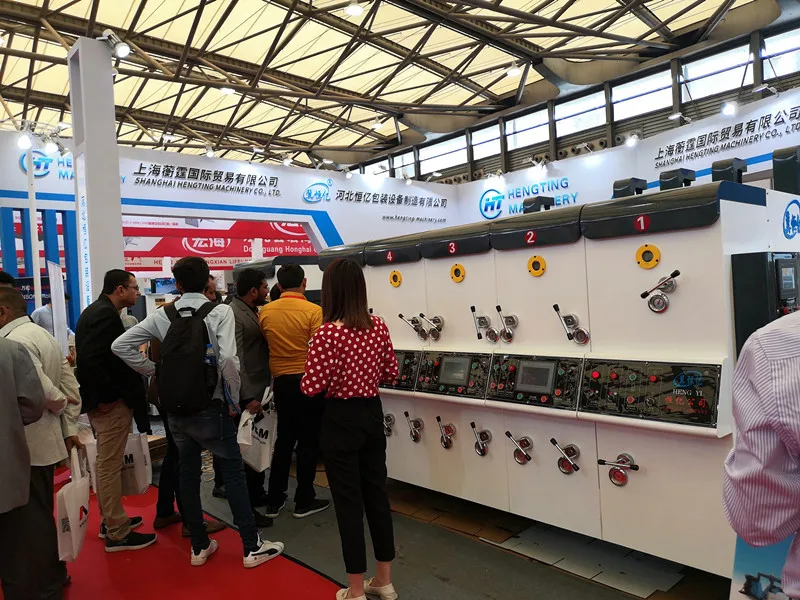

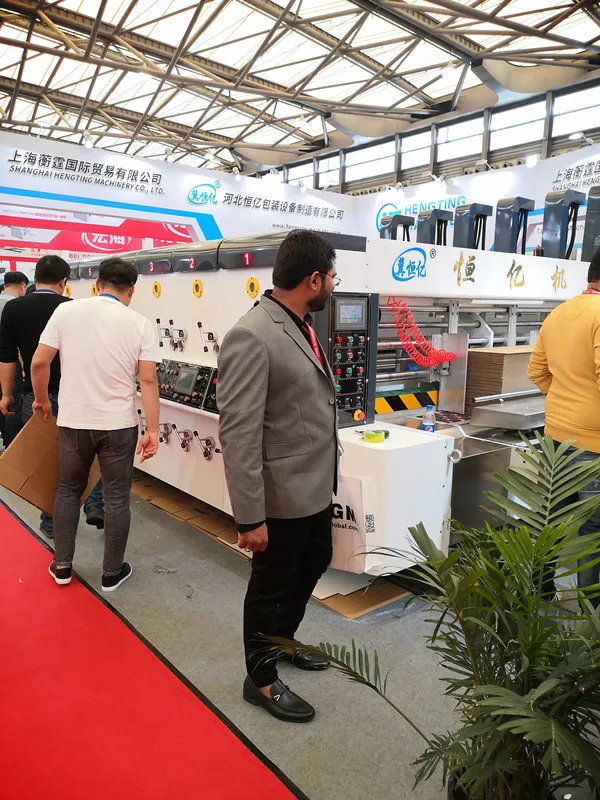

Hebei Hengyi Machinery Co.,Ltd

Business Type:Manufacturer

Main Products: High Speed Printing Slot MachineMedium Speed Printing Slotting (four-mode die cutting)High Speed Rotary Die Cutting MachineHigh Speed corrugated Paperboard Production line Fingerless Type Single FacerPaper sheet delivery and side conveyerNC Spiral knife cut off machineAutomatic folder gluer machineHigh speed semi-automatic nail box machineThin Blade Slitter Scorer

view on mobile

Newest 5 ply corrugated cardboard box production line machine

Manufacturing & Processing Machinery Packaging & Printing Machine

MOQ:1 Piece(s)

Payment Method : L/C T/T D/P

Keywords:cardboard production line carton box making machine corrugated cardboard plant automatic making machine automatic box making machine 5 ply corrugated line 7 ply corrugated line 2 ply line corrugated carton box line