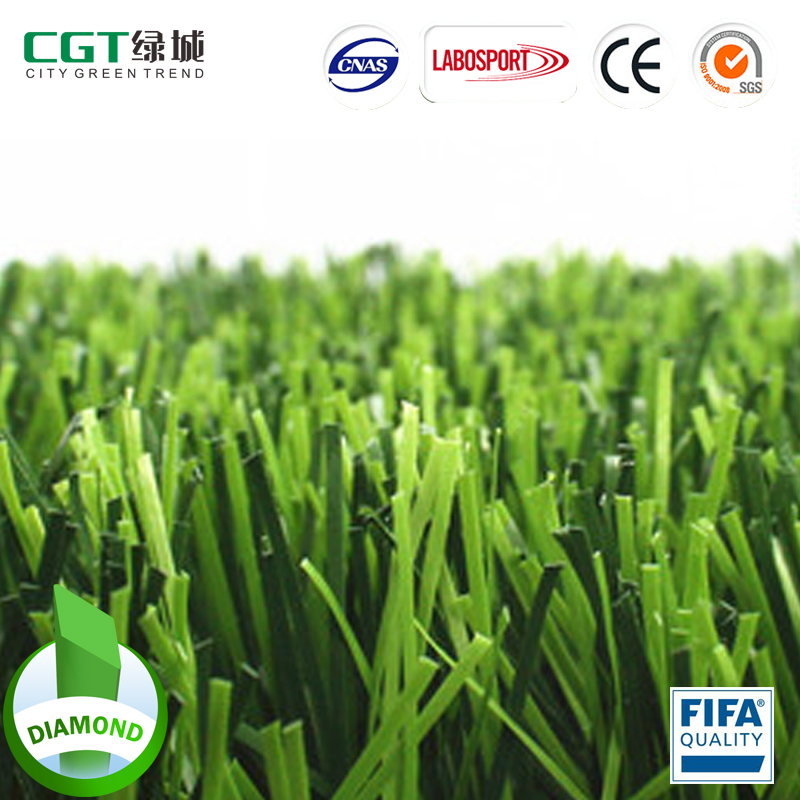

FIFA QUALITY football grass for professional-level match

Sports,Games & Gifts Outdoor Sports

FOB Price:US$ 8.00 / Square Meter(s)

MOQ:1000 Square Meter(s)

Payment Method : L/C T/T Western Union Paypal Money Gram

Keywords:football turf FIFA FIELD Sport turf

Products of the same category