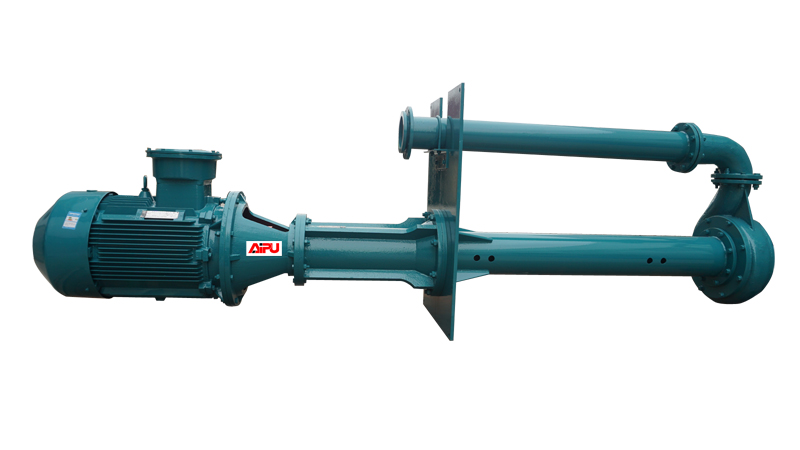

Submersible Slurry Pump

Oil & Gas Oil and Gas Exploitation

FOB Price:US$ 1,089.00 / Piece(s)

MOQ:1 Piece(s)

Payment Method : L/C T/T

Keywords:Submersible slurry pump Slurry pump

Products of the same category