Guangxi Hongfa Heavy Machinery Co., LTD

Business Type:Manufacturer

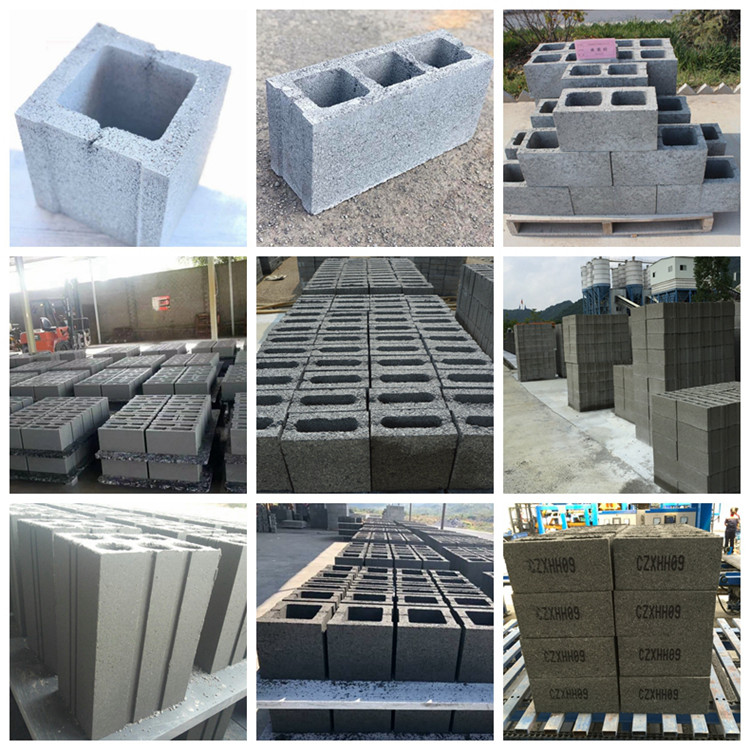

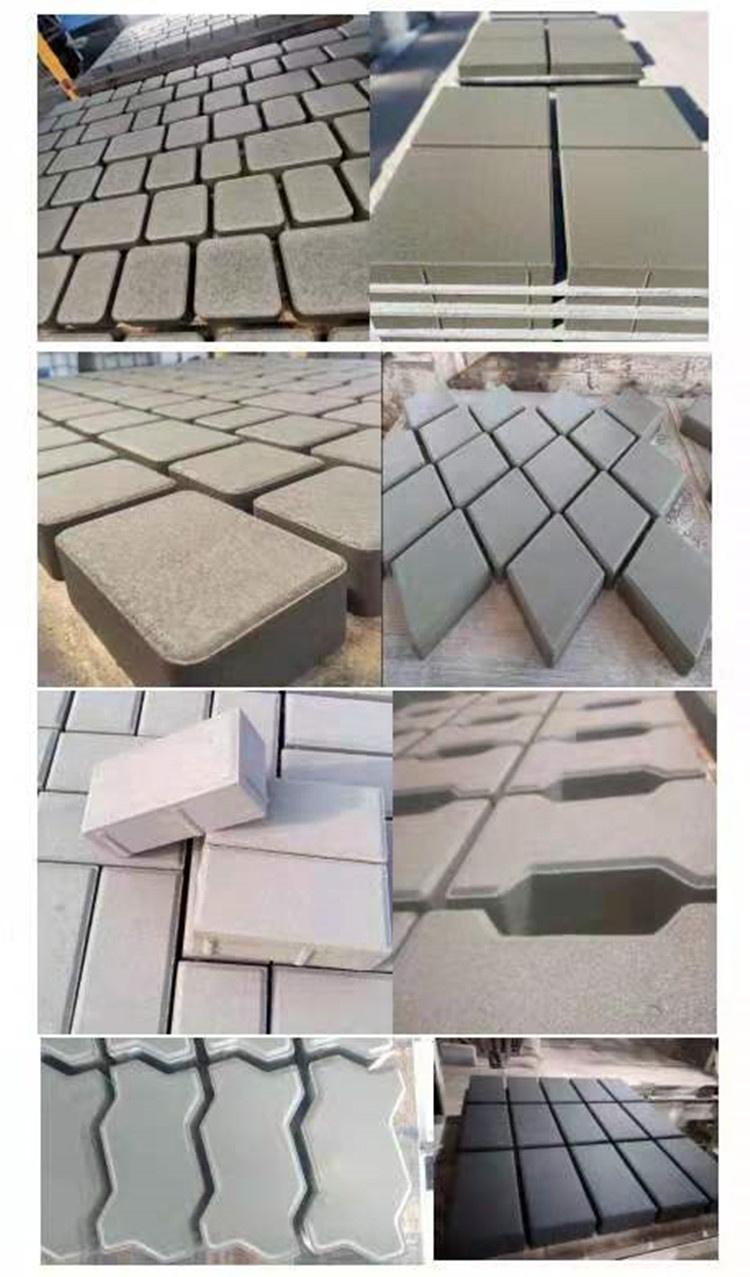

Main Products: concrete block machineAAC block production lineconcrete roof tile machineConcrete Batching Plantconcrete pipe machineAgricultural Sprayerartificial quartz slab machinefloor tile machineEPS Cement sandwich lightweight wall panel machinePrecast concrete slat machine

view on mobile

Adobe 2021 brick machine to making curbstones hollow block interlocking pavements business idea

Manufacturing & Processing Machinery Engineering & Construction Machinery

MOQ:1 Set(s)

Payment Method : L/C T/T

Keywords:adobe 2021 brick machine curbstones moulding interlocking pavements business idea Brick Making Machinery block making machinery cement block machine