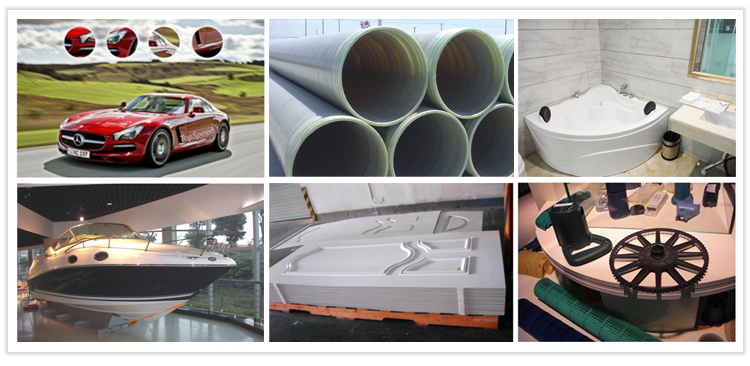

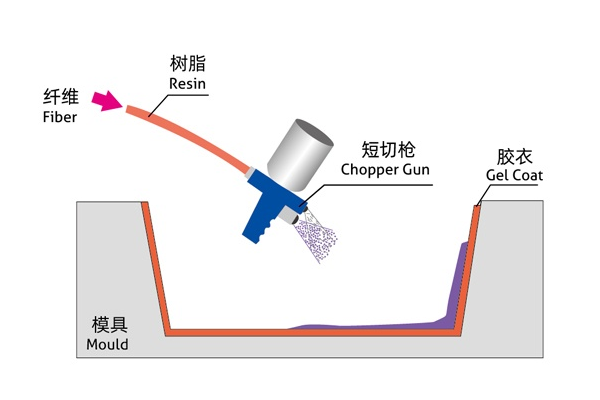

Fiberglass assembled roving for spray up(Gun roving for batchtub,swimming pool)

Metallurgy,Chemicals & Energy Composite Materials

FOB Price:US$ 1,290.00 / Ton(s)

MOQ:1 Ton(s)

Payment Method : L/C T/T Western Union Paypal

Keywords:E-Glass Spray up Roving Gun roving for batchtub swimming pool Fiberglass Gun Roving 2400tex Spray Up Roving Chop Roving

Products of the same category