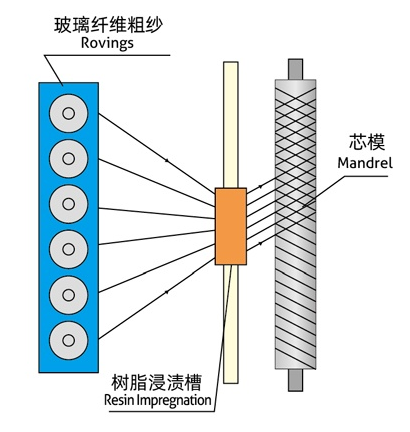

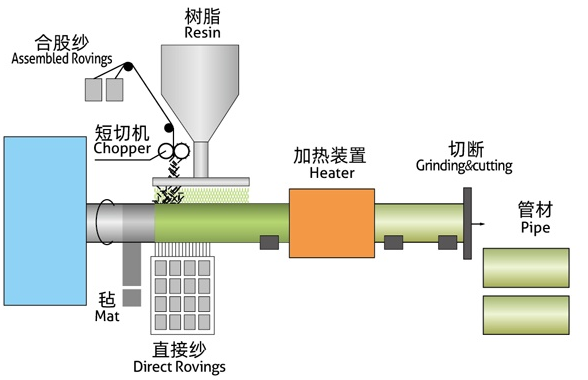

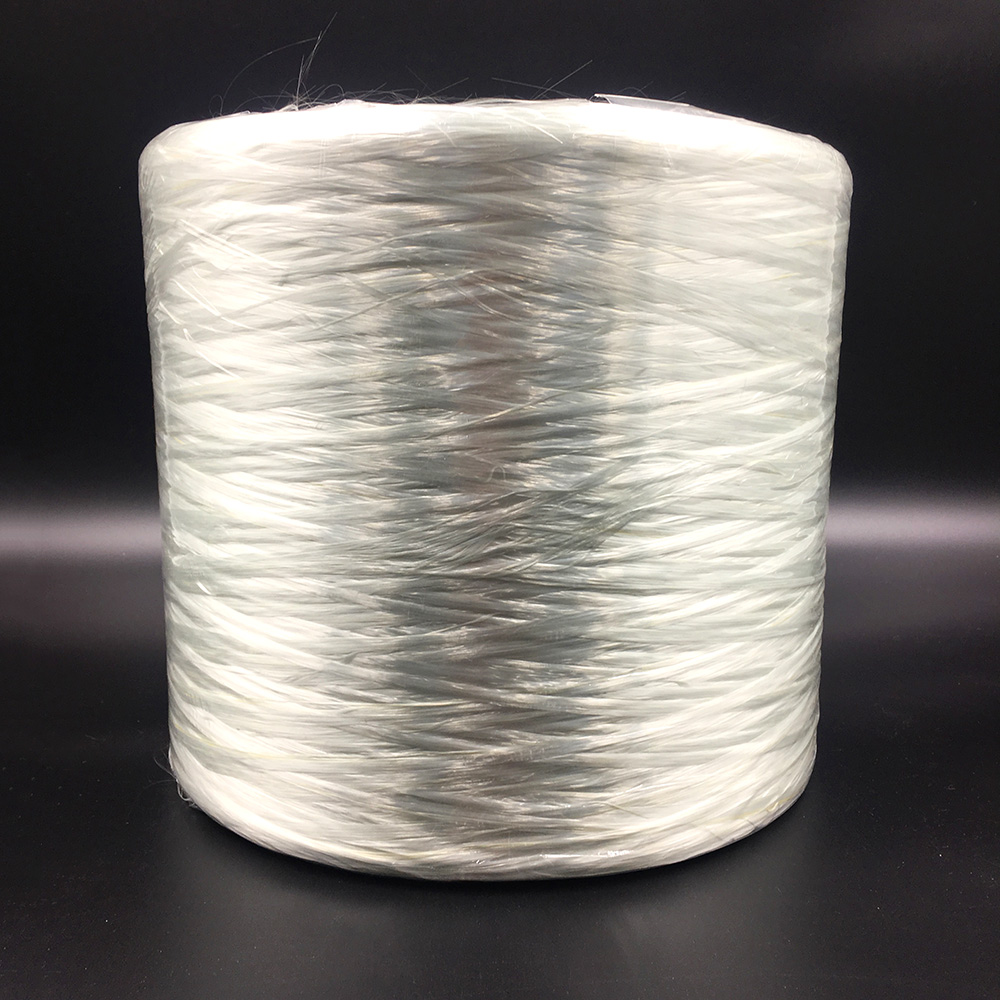

Direct Roving for Filament Winding,Pultrusion ,Weaving,

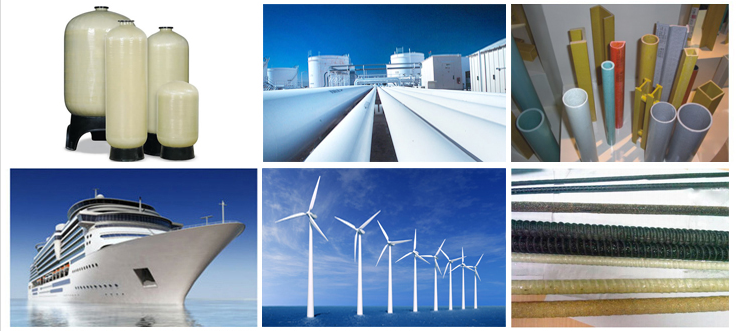

Metallurgy,Chemicals & Energy Composite Materials

FOB Price:US$ 0.75 / Ton(s)

MOQ:1 Ton(s)

Payment Method : L/C T/T Western Union Paypal

Keywords:A Grade Grc Glass Fibre Roving Filament Winding Roving Roving for Weaving Single end roving

Products of the same category