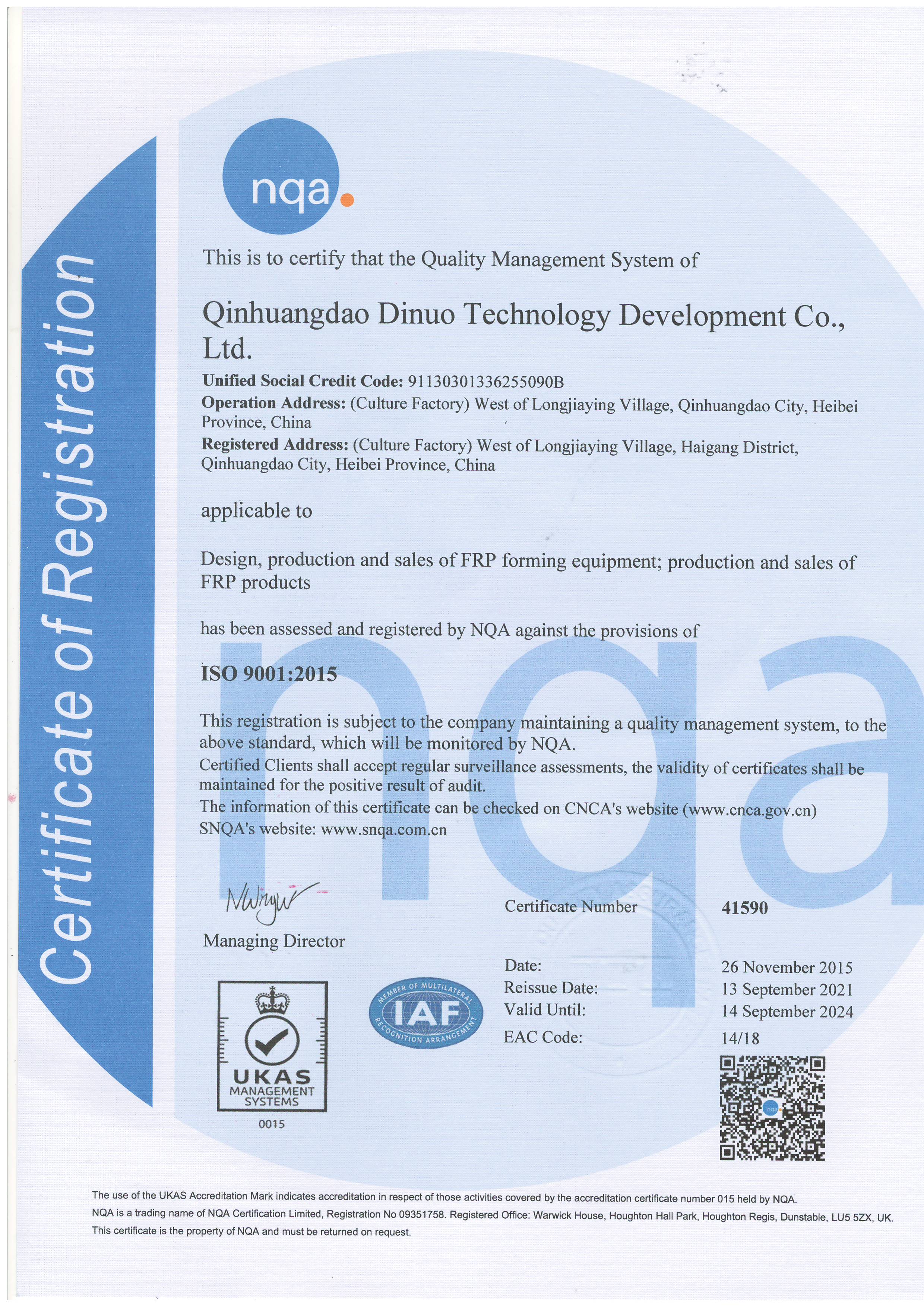

Qinhuangdao Dinuo Technology Development Co.,Ltd

Business Type:Manufacturer

Main Products: fiberglass sheet making machineFRP Roofing Sheet MachineFRP Gel Coat Sheet MachineFRP gutter machine3.2m width gel coat sheet making machinefiberglass corrugated sheet production lineGRP skylight roofing panel production lineGRP sheet production line

view on mobile

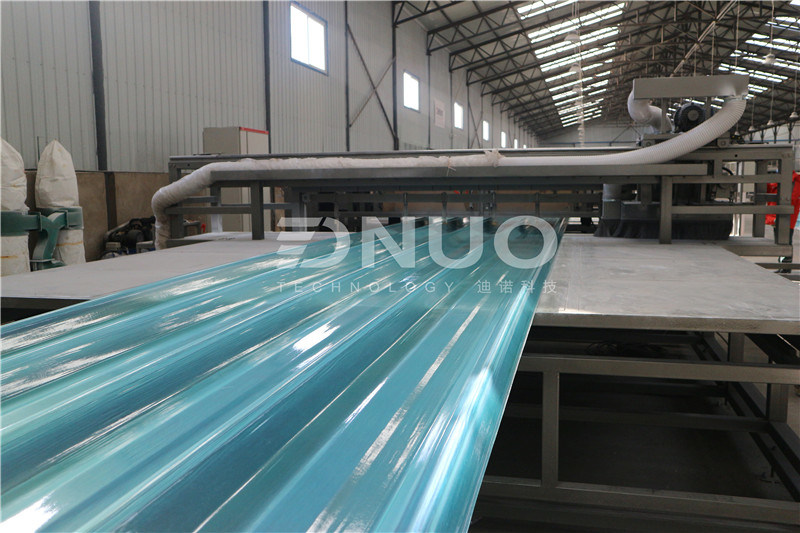

FRP GRP fiberglass plastic sheet production line LS

Manufacturing & Processing Machinery Industrial Processing Machinery

MOQ:1 Set(s)

Payment Method : L/C T/T

Keywords:fiber sheet making machine frp corrugated sheet machine machine making fiber sheet FRP sheet machine prfv fiberglass sheet machine frp sheet production line PRFV sheet making machine GRP light sheet machine GRP roofing sheet machine GRP panel machine