BLUEWAV

Business Type:Manufacturer

Main Products: Hypochlorous Acid Anolyte GeneratorAir Disinfection MachineChlorine dioxide Generatoron site chlorine gas generatorUV SterilizationOzone GeneratorAlkaline ionized water machineSodium Hypochlorite Generator Medical Grade Hypochlorous Acid Anolyte Generator

view on mobile

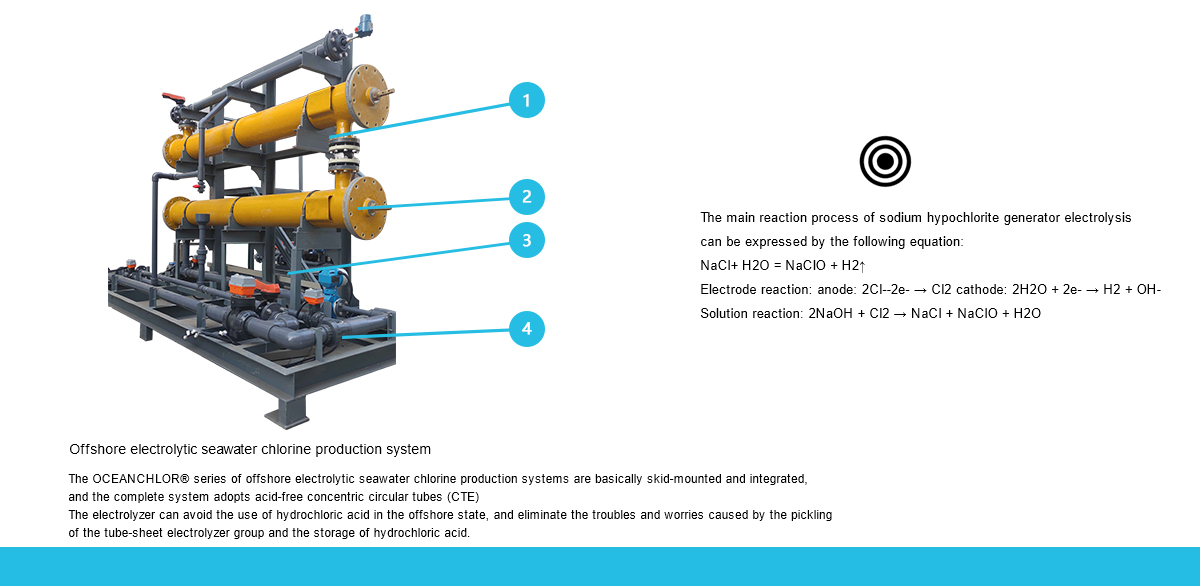

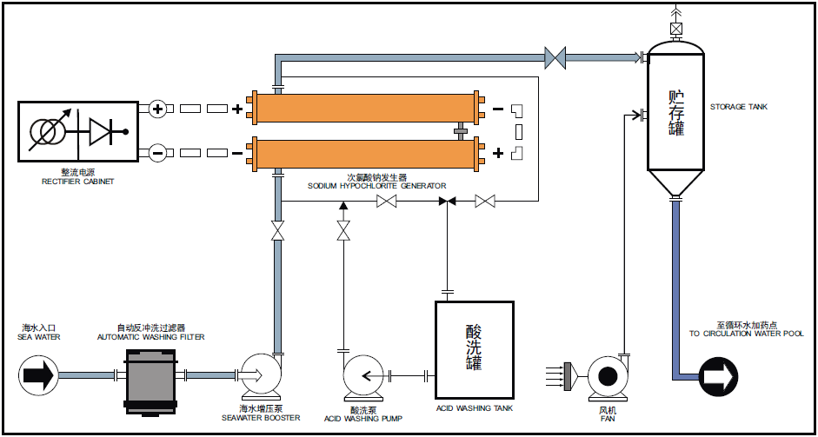

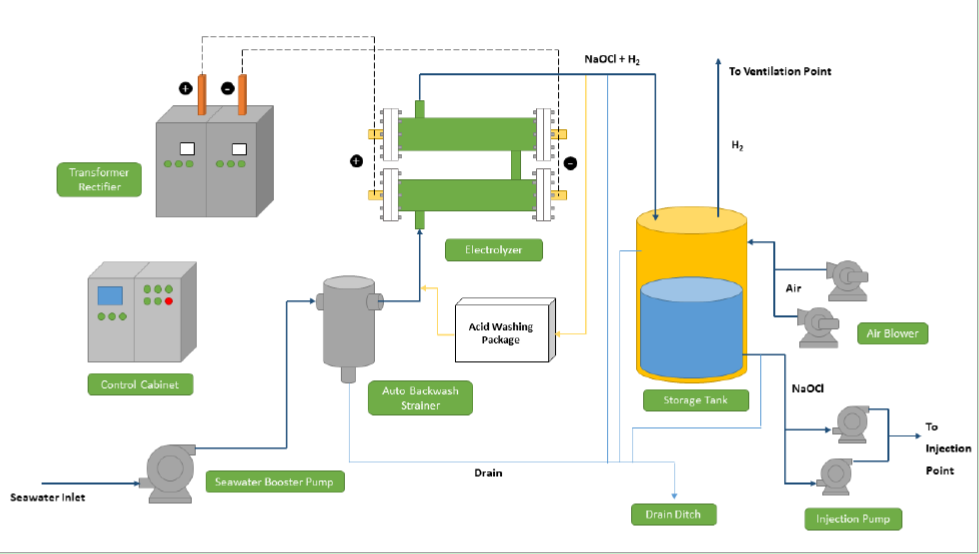

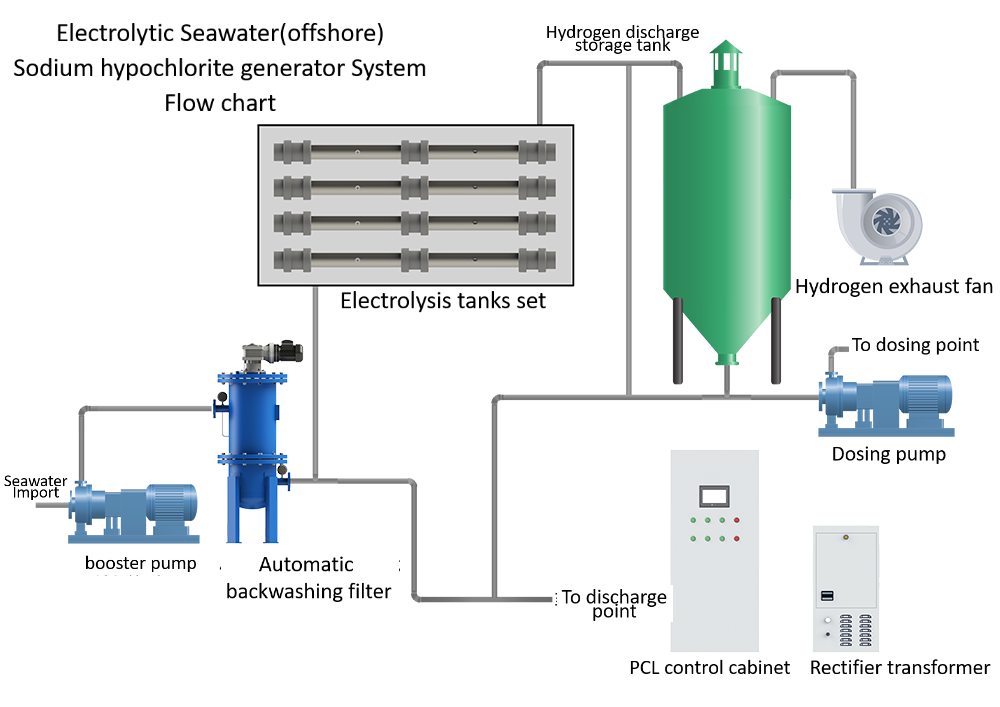

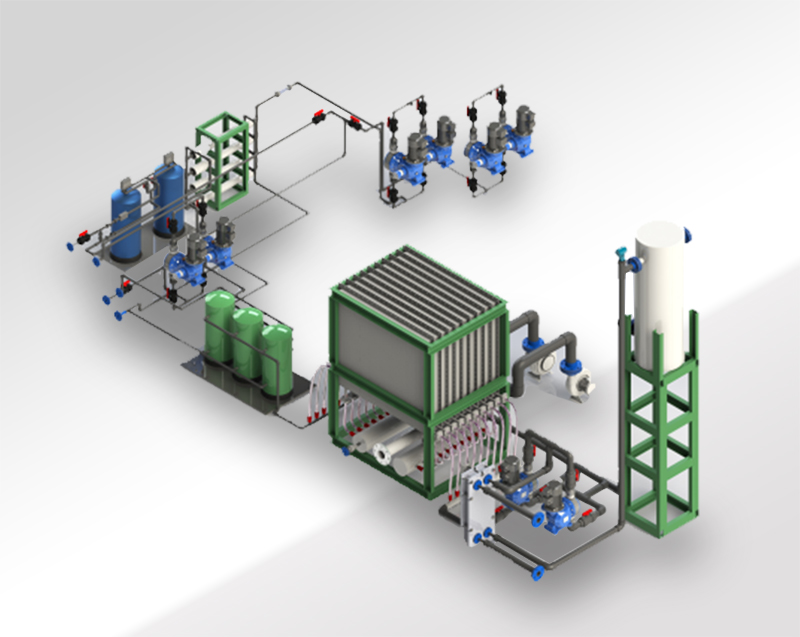

Offshore Electrolytic Seawater Chlorine Production System

Manufacturing & Processing Machinery Water treatment & Environment

MOQ:1 Piece(s)

Payment Method : L/C T/T D/P Western Union Money Gram Others

Keywords:Sodium Hypochlorite Generator electro chlorination system NaCLO generator chlorine production system seawater chlorination system seawater chlorination package brine chlorination package brine chlorination system Water Treatment seawater treatment